Throughout history, people have tried to control the forces of nature. In order to convert natural resources into needed goods and services, he has employed labor and capital. Labor has been used to control the forces of nature to the point where it is possible to change the form of the materials and to exploit capital.

Tools ranging from basic stone tools to highly complex and specialized devices like computers, atomic accelerators, and synthetic materials have been used in this study. Older technologies have given way to these new ones. Technology advancements are a result of businesses trying to maximize profits.

The economic advantages of a new idea have created an excellent reason to create and employ technologies that support almost all direct and indirect production processes. As a result, the production processes are now physically separated, and the significance of exact production control and efficient marketing has grown.

In Product and Service Production:

A successful businessperson needs a sharpened pencil to put ideas into words and to write those words down. He gets up, has breakfast, reads the newspaper, goes shopping for food, clothes, shelter, and energy. He lives in a world of goods and services, rarely having to give anything other than the oxygen he breathes.

The modern economy would then be viewed as an advanced organization that efficiently manages resources through the use of financial markets. This basically indicates that some goods and services are produced where costs are lowest, and that these are the goods and services that people need the most.

The few people and their families who are almost independent are served by a relatively small portion of the world’s productive resources.

The organization of the production and distribution of goods and services is the focus of the business world, and businesses use specialized knowledge and abilities to achieve this productive purpose.

Technology is the application of equipment and machinery, as well as human processes and procedures, to the production and sale of goods and services.

Production Efficiency with Technology:

In the modern world, the supply chain appears to be becoming more and more complex. The globalized context that modern supply chains work in causes constant change in the surrounding conditions.

This increases a company’s struggle to maintain a competitive edge in its particular market. Supply chain solutions with a focus on technology can help businesses become more flexible, transparent, and adaptable in order to maintain the lowest possible cost of ownership.

Each of the following technologies has the potential to significantly change our understanding of supply chain management: robotics, artificial intelligence, driverless cars, big data, 3D printing, the Internet of Things, blockchain technology, and drones.

An abundance of new opportunities arises from the closer-than-ever linkages between the e-commerce and logistics and transportation sectors. These relationships can be used with the right modern supply chain technology.

Industrial Internet of Things (IoT):

An increasing number of related, networked devices are being used in supply chain management as the Internet of Things spreads throughout the manufacturing sector. IoT is regarded as having a strong potential for impacting both internal and external supply chain activities because it is a relatively new technology.

The platform that allows organizations to obtain this is provided by the capacity to gather such a large amount of data, ranging from location and status to other data points. The IoT is being used in three different categories. As manufacturing grows increasingly complex, itemization—the capacity to have RIFD chips and sensors on a growing number of items—occurs.

The capacity to monitor anything from ships and containers to pallets, as well as the ability to track an expanding number of problematic products and items moving through the supply chain, is known as tracking and tracing.

Interactivity is the way that several IoT-enabled components work together or interact with one another. Examples of this include automated replenishment of inventory levels and scrapping of a portion.

Automation and Robotics in Warehousing and Logistics.

The emergence of mobile robots in warehouses, specifically the warehouse-centric distribution optimization idea, is replacing it and bringing logistics strategies closer to drastically reduced transportation costs and inventory levels that were previously considered unaffordable.

Even though it seems almost obvious that widespread automation will definitely result in the loss of lower-skilled, lower-paid workers, that conclusion is essentially an assumption.

In other words, although jobs in hangars, pits, and farms have decreased significantly throughout American history, more people may be employed as farmers by 2050 than there are now.

It is difficult to estimate exactly what such work will entail because of the various features of the waves of technological progress that could occur between now and 2050.

The current state of mobile robotic technology is precisely focused on determining its physical qualities, and nowhere is this more apparent than in the warehouse.

Talk about labor market disruptions is typically couched in apocalyptic language. The Great Depression’s devastation of the labor market gave rise to the New Deal.

Many believe that the United States is on the verge of an AI-caused unemployment catastrophe, and the Rust Belt is still rusting. It seems that the new rebels are robots.

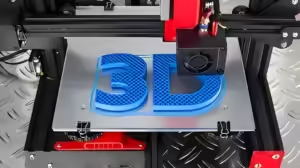

Additive manufacturing and 3D printing:

What is additive manufacturing and what manufacturing applications can it help with?

Is it the way of the future for aerospace? Many companies have been afflicted by these questions, just as I have been. For me, there was more to the solution than just going out and purchasing a machine.

First of all, a significant investment is needed not just in the technology itself but also in the associated workers needed to operate the machine, the equipment needed for component handling and post-machining, the energy consumption of the machine, material handling, and other activities.

The process of creating three-dimensional objects from a digital file is known as additive manufacturing. Rather than eliminating material, an object would be manufactured by additive manufacturing by layering on materials until the desired form is achieved.

Take milling, for example. One of the main advantages of this technology is that, by creating items from 3D digital data, AM makes it possible to achieve significantly shorter lead times—from concept to product.

Trading has been completely transformed by this technology, which makes it simple, quick, and inexpensive to build custom parts and products that are tailored to each customer’s needs. For instance, AM is thought to sit at the nexus of material powder recycling and printing in the context of Industry 4.0, allowing for both flexible and sustainable production.

Uses in Diverse Sectors:

This section evaluates how technologies associated with the industry 4.0 paradigm are affecting a number of production sectors, including the automobile, pharmaceutical, garment, textile, and electrical and electronics industries. These technologies have been investigated and put to use on several manufacturing facilities’ production lines.

The application of technology related to the “Industry 4.0” paradigm in various industries has produced encouraging results.

New technologies that have emerged from Industry 4.0 will likely design various industrial processes in the near future in order to improve productivity, performance, and product quality as well as new products that could not be developed with the technology available today.

Future Trends and Challenges:

To address all of these issues, a number of works have been recently created with the goal of making Industry 4.0 easier to adopt. In addition, there have been a lot of current trends that highlight the shortcomings and potential upgrades of these technologies. In this way, the most significant current trends in Industry 4.0 are described. The recently released review of numerous authors’ contributions in a special edition of the Reliability journal provided support for this approach.

Obstacles.

Industry 4.0 adoption is not at all simple and is characterized by a number of issues, including high implementation costs, long investment return periods, resistance from the current workforce when interfacing with new technologies, and the need for both new and existing employees to receive education and training. An outline of those main difficulties is provided in this module.

E-commerce: Definition and Scope.

The process of facilitating the exchange of money, products, services, and information via the Internet.

E-commerce includes ordering and payment procedures, product deliveries and marketing, as well as customer support. It can be carried out between businesses and customers, or between businesses and other businesses, or between businesses and suppliers, banks, and commercial payment networks.

The two standout systems that provide independent e-commerce capabilities are electronic data interchange and enterprise resource planning. Using an electronic payment gateway becomes even more important in light of the e-commerce process’ growing complexity.

Basis.

The basis of small and medium-sized businesses in China is e-commerce. Growing on the international e-commerce “stage,” China’s small and medium-sized businesses are becoming more significant players thanks to new technology and Internet platforms.

This model provides Chinese companies with more effective solutions to withstand the fierce competition from powerful enterprises. In addition, it draws attention to China’s e-commerce from around the globe.

This is in addition to the import and export business strategy and logistics delivery that accompany the e-commerce portal. China’s e-commerce is gradually making its way to the top platform in the globe. With adaptable business concepts, inventiveness, bravery to adopt a new way of thinking, and an unquenchable spirit, one may rival globally recognized brands.

Significance for the Modern Business World:

Despite the advent of new technologies, this field is able to withstand fast and dynamic change. In this context, a number of analysts have projected that mobile commerce will be used by over a billion people globally.

This essentially states that there are huge economic opportunities connected to the growth and application of m-commerce in the corporate sector.

M-commerce apps will undoubtedly take the lead in sales channels as mobile devices with advanced capabilities, such as smartphones and tablets, begin to proliferate.

Conclusion:

It also describes particular research issues and corporate interaction sectors linked to the primary subjects of this article. Based on preliminary data, technology may promote reciprocal cooperation between businesses.

Examples of the various technologies that assist business today and will be demonstrated include cloud computing, artificial intelligence, and mobile. Therefore, it is illogical to believe that business does not exist in the context of technology.